Development – innovations at the highest level

Berger is renowned both nationally and globally, as a pioneer and a leader of innovation. The company has represented the highest quality standards, specialisation and innovative strength for decades, and therefore since the birth of the industrial coating segment.

During these decades, Berger has therefore also received regular accolades for its special innovative power and outstanding products. An example of this is the award of the top score of A+ in the “Germany TOP100 Innovator 2016” prize.

This makes us both proud and grateful, and also motivates us to continue improving and investing in new products, further developments and innovations. Today, we therefore consistently and continuously reinvest a large part of our annual turnover into innovation and development, specifically in the latest technical equipment and highly qualified specialist personnel.

Our motivated development team consists of an optimal mix of specialists: young talents, development professionals with decades of experience, chemists with doctorates, application technicians, paint technicians and lab assistants. This ideal mix, combined with a high level of personal responsibility, guarantees continuous and substantial dynamism and new initiatives. This means that roughly 25% of our staff now wear a “white coat”, and focus exclusively on this aspect.

This enables us to integrate the diversity of the almost infinite world of raw materials and the latest legal developments. We are in permanent and close contact with raw material producers, authorities and associations. We also prioritise the full and balanced integration of chemical-technical theory and practice, and chemists and application engineers make an essential contribution here. This enables us to achieve technically intelligent systems that work reliably in practice.

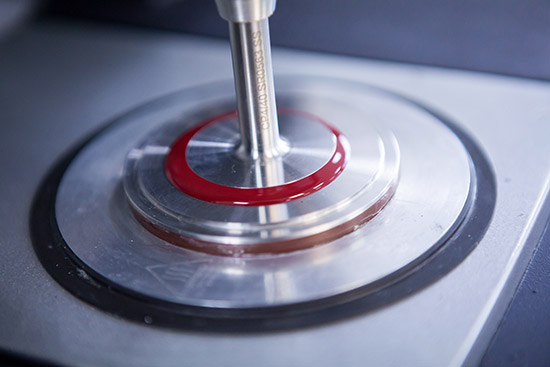

These are backed up by our comprehensive [Z] BERGER-ZOBEL testing technology. A coating has up to 100 different evaluation characteristics, which we define, test and record individually and comprehensively for each system. This process is applied to every semi-finished product and raw material not only during development, but also to every production batch. Wall-to-wall quality.

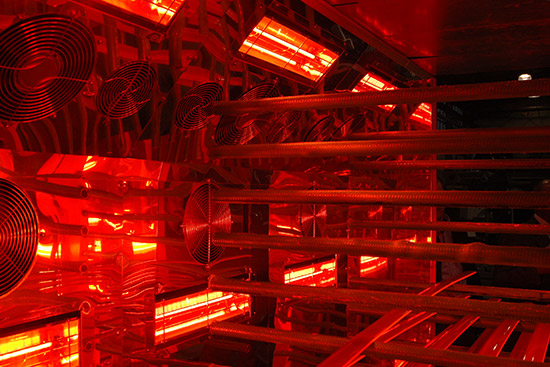

Our climate test procedure, for example, is unique. The research and development team and the application technology department develop and test each system for its practical suitability in specifically designed climate chambers and using defined test scenarios. This is how we imitate all four extreme climates from cold/humid, through warm/humid and cold/dry to warm/dry.

Only products that also pass these strict procedures will be ready to launch on the [Z] BERGER-ZOBEL market. These products are now available all over the world… in Siberia, Singapore, USA, Australia, Iceland, Denmark and of course Germany and used by satisfied customers.

In a nutshell: Top development performance from outstanding specialists, state-of-the-art technology and almost 100 years of experience as a specialist.